Die Casting

News

What Are The Benefits Of CNC Machining?

CNC machining has wide applications in industrial part manufacturing due to several advantages. Below are a few benefits of the process over other manufacturing operations.

4 Main Steps For CNC Machining Process

There are four basic steps to CNC machining, no matter your CNC machining process. Below is a stepwise procedure on how they generally function:

Heated Forging Equipment - International Foundry, Die Casting & Forging

Heating forging equipment is a non-standard induction heating equipment that adopts the principle of electromagnetic heating. It is mainly designed and manufactured for round steel, steel plate, steel pipe, aluminum rod, stainless steel rod, copper rod and other metal materials such as alloy steel, stainless steel and alloy aluminum before forging. It is conducive to forging heating automation and high heating efficiency, and has become the first choice for metal heating equipment in the forging heating industry. Haishan Electromechanical Xiaobian will introduce this heating forging equipment.

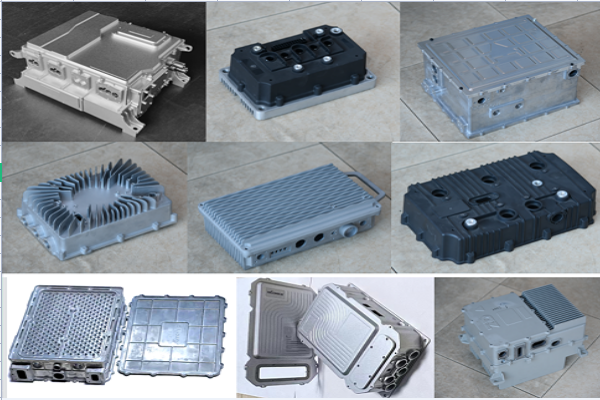

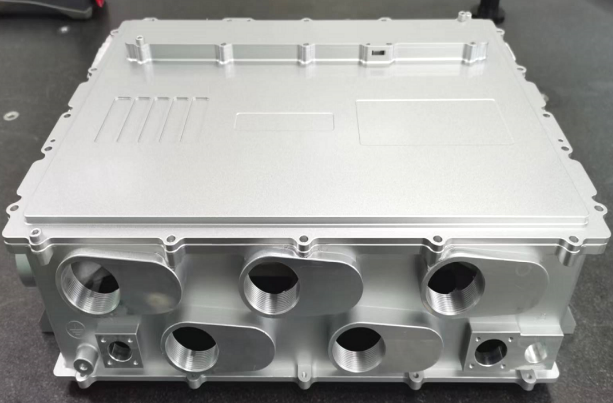

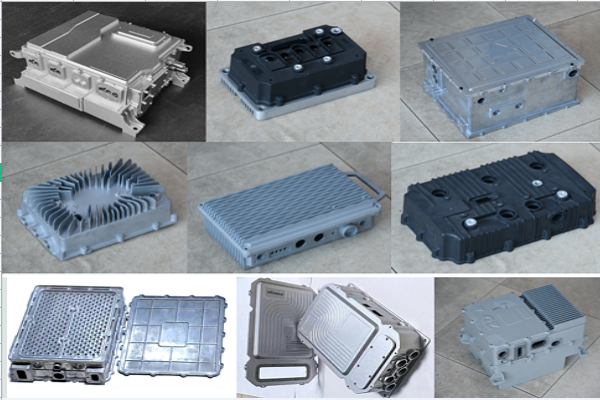

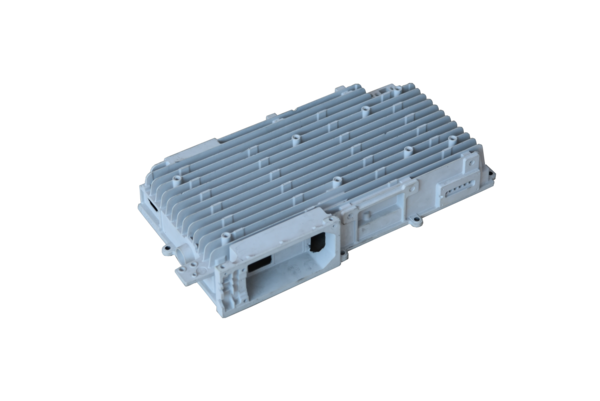

Aluminum Alloy Die Casting Design Points

The rationality of die-casting design is related to the entire die-casting process. When designing die-castings, the structural characteristics of die-castings and the process requirements of die-casting should be fully considered to minimize the defects of the designed die-castings during the die-casting process. occur, and improve the quality of die castings to the greatest extent with the optimal design scheme.

What are the advantages of high temperature die-casting machine mold temperature controller in die-casting process?

What advantages does the mold temperature controller of high-temperature die-casting machine have in the use of die-casting process?

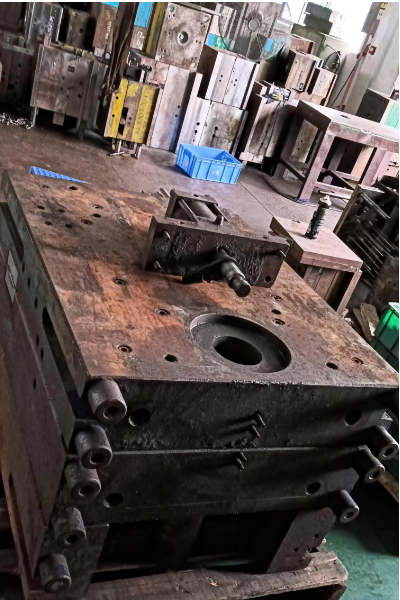

Processing technology of die casting mold parts

Die casting is a commonly used metal casting process that uses a mold cavity to apply high pressure to molten metal to obtain a metal material that conforms to the shape of the mold cavity. The mold used in die casting is the most important part of the whole process equipment.

Analysis of Vacuum Die Casting Technology

Vacuum die-casting method is an advanced die-casting process that eliminates or significantly reduces the pores and dissolved gases in die-casting parts by removing the gas in the die-casting mold cavity during the die-casting process, thereby improving the mechanical properties and surface quality of die-casting parts.

Talk about the relationship between the quality and output of die casting products

The performance of die-casting product quality in the R&D stage and the mass production stage, as well as the main aspects that should be paid attention to in order to improve quality and output in the two stages, and suggestions for improving product quality.

Influence of Die Casting Die Structure on Casting Quality

Influence of Die Casting Die Structure on Casting Quality

Surface Strengthening and Modification Technology of Die Casting Mold

Summary of Die Casting Mold Surface Strengthening Technology

Description of the characteristics of the anodizing process of die-casting aluminum

Both the natural color anodizing process and the black anodizing process are a kind of anodizing process, and there are only differences in some processes.

What are the benefits of impregnating aluminum alloy die castings

Aluminum alloy die casting infiltration is a new type of casting process. Its main principle is to make the foam molding model the same as the Styrofoam casting, and then dip the aluminum alloy die-casting parts into special refractory material coating, drying and packaging. , pouring, replacing the foam pattern with metal solution until the casting is produced, then cooling, dedusting, static selection and magnetic selection of the used sand to obtain clean, suitable dry sand, roughly called white zone, red zone, black zone District section.

Two Polishing Processes for Aluminum Alloy Die Castings

The surface technology of aluminum alloy die castings is rich and varied

Aluminum alloy die casting development history

The development history of die-casting is divided into different opinions. According to the records of relevant articles, die-casting lead appeared at first.

_1693897497181.jpg)